More information

Shangshui

Hotline: +86-20-82315199 / 82526173 13922930758

Fax: +86-20-82300173

E-mail: hnlgxcj@163.com / info@gzsep.com

Add.: 9th Floor, Aluminum Association Building, 70 Lingnan Road, Dali Town, Nanhai District, Foshan City

Service double carbon and double cycle

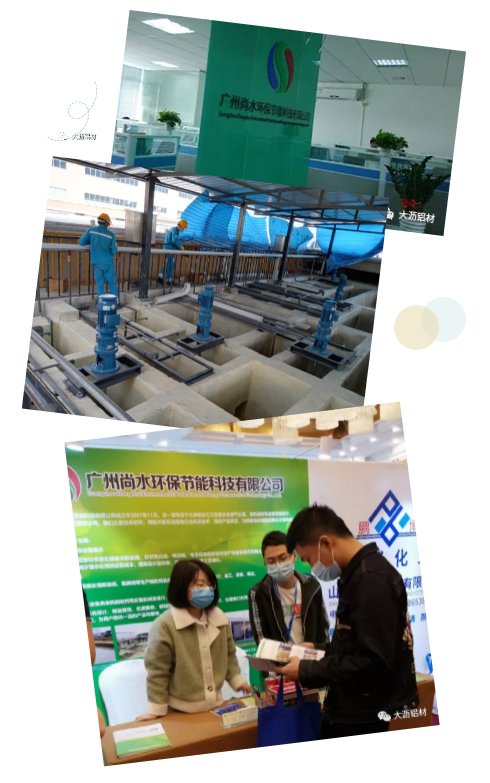

In the post epidemic era, the concept of double circulation will promote the new pattern of development. "Cultivating new opportunities in crisis and opening a new situation in changing situations" is the development plan of aluminum processing enterprises. In this new era, Guangzhou Shangshui environmental protection and energy saving Technology Co., Ltd., the governing unit of Guangdong (Nanhai) aluminum processing industry alliance, adheres to the principle of seeking progress while maintaining stability and seizes the first opportunity for high-quality development. Next, we will show you its style, share experience and create a new situation in the aluminum processing industry.

Guangzhou Shangshui environmental protection and energy saving Technology Co., Ltd. (hereinafter referred to as "Guangzhou Shangshui") is a professional environmental protection and energy saving technology company, established in 2007. Mainly engaged in R & D, design, construction, installation, commissioning, service and equipment development and manufacturing of environmental protection and energy-saving systems. Despite the sudden outbreak of the epidemic, Guangzhou Shangshui has always ensured the stability of the project. In the past 14 years, through in-depth understanding of customer needs, targeted provision of high-quality solutions and high-quality implementation, it has provided customers with satisfactory solutions to improve production efficiency.

After the central government put forward the "double carbon" strategy and "double cycle" strategy, Guangzhou Shangshui was encouraged and believed that environmental protection and energy conservation were paid more and more attention, and the aluminum industry had greater development space, especially in strategic emerging industries such as photovoltaic. Therefore, it hoped to give full play to its advantages and provide better solutions for customers.

Corporate business

Water treatment

R & D and project undertaking of resource utilization technologies such as various wastewater treatment (especially wastewater from aluminum processing industry) and reuse systems, water supply and pure water treatment systems, circulating water treatment systems, zero discharge of sewage from factories and communities, heat pump and MVR evaporation, concentration and crystallization systems, anaerobic biogas production and heavy metal recovery.

Conserve energy ,reduce emissions

R & D and project undertaking of various energy-saving transformation projects such as flue gas and wastewater waste heat recovery system, heat pump system, hot water reuse system and motor drive, and energy-saving and emission reduction technologies such as energy-saving aeration system of sewage plant.

Waste gas treatment

R &D and project undertaking of air treatment technologies such as industrial organic waste gas treatment, air pollution control of commercial and civil buildings, air purification and process air conditioning system, acid mist treatment, various dust treatment, recovery of valuable resources such as organic solvents, etc.

Customer case

1. A customer's annual output of 20000 tons of aluminum profile oxidation electrophoresis and spraying wastewater treatment project. The project contains oxidation electrophoresis water washing wastewater, powder spraying wastewater, pre-treatment wastewater before painting and water curtain water, which are divided into nickel containing wastewater, nickel containing fluorine containing wastewater, fluorine containing wastewater, acid wastewater, alkaline wastewater, organic wastewater and waste tank liquid. Guangzhou Shangshui has formulated a comprehensive treatment scheme by comprehensively analyzing the water quality, quantity and discharge characteristics of various wastewater, Use R & D and practical experience to solve the problems of fluorine-containing wastewater treatment, reasonably classify and treat them, do a good job in elevation and plane design, select equipment with good cost performance and high reliability, and combine it with self-made non-standard equipment, so as to stably meet the requirements of discharge standards with appropriate investment and low operation cost.

2. A customer's flue gas waste heat utilization project. The project uses the medium and low temperature flue gas discharged from the vertical pusher furnace of the factory to heat the rolling oil, which has achieved remarkable energy-saving effect without affecting the production of the vertical pusher furnace and the rolling system. The system adopts high-efficiency flue gas heat exchanger combined with residual pressure control system and rolling oil temperature control system, and adopts intelligent control system to automatically switch flue gas waste heat system and electric heating system in real time, so as to maximize the use of flue gas waste heat instead of electric heating on the premise of ensuring production.

3. Zero wastewater discharge project of a customer. In this project, the cleaning wastewater of the spraying production line is collected and pretreated. The membrane method is used to recover pure water and concentrate the wastewater, and then the vacuum heat pump evaporation and concentration system is used to further recover distilled water, concentrate and crystallize the wastewater pollutants, so as to realize water recycling and near zero discharge. Because membrane concentration is adopted first, and then high-efficiency and energy-saving vacuum heat pump evaporation concentration technology is adopted, the cost of per ton water treatment is greatly reduced, so that zero emission can be realized economically and the problem of environmental emission can be completely solved.

System innovation, optimized design, lean management, high-quality service and exceeding user needs are the quality policy of Guangzhou Shangshui and its commitment to users. Guangzhou Shangshui will, as always, strive to explore and innovate, and provide customers with first-class products and services.